Get Quote

News

- Wire EDM Machine consumable partsDIC-206 is energy-saving and emission-reduction type WEDM fluid. The formula of DIC-206 Water-Soluble WEDM Concentrate is completely made up of water-soluble materials. Electrical corrosion products can disperse in the water solution quickly, and could be separated after sedimentation and filtration. Rat oral acute toxicity tests result is "non-observed toxicity". No black sludge will emerge on the cutting surface of workpiece. It is the best working fluid for [Medium speed WEDM" (NC reciprocating travelling wire electrical-discharge machines with repeated cut function); with outstanding features of health and safety and so on. All of the RoHS Directive items testing results are [N/D" (not detected). Working Concentration: Concentrate has to be diluted by pure water (DI water). Suitable working concentration is recommended in the operating manual. It shall be check by handhold refractometer WY-20R. Supplementing water is necessary every shift in daily work. After that, checking and judging if supplementing DIC-206 concentrate is necessary must be done. Since the boiling points of effective components in working fluid are higher than water, the concentration will generally increase if water is not supplemented. Application: 1. A suitable filter (we can offer) must be installed on the exit of circulating pump to remove larger particles of electrical corrosion products. Then, the effect of cutting process could be ensured, and the using term of working fluid could be long. 2. DIC-206 cannot be blended with other WEDM fluids for use. 3. When using DIC-206 instead of emulsion coolant, the following steps shall be done: A. The whole fluid feeding and circulating system, after draining off the previous emulsion, shall be cleaned thoroughly with suitable cleaning agent. B. The machining parameters shall be regulated: increasing the electric current and the feed rate properly. 4. If there are some oxidation products leaving on the machined surface of workpieces after operating with DIC-206, use alcohol to erase. Or, grit blasting can get better effect. 5. Rust protection of workpieces and other ferrous metal parts must be done every week, using 16.7% working fluid coating on the surfaces to be protected with brush or other adequate tools. 6. Electrical corrosion products that leave on the bridge board, bracket and operating platform shall be cleaned up often (about one or two times one week). Note: 1. We highly recommend you to use DI water! 2. It is possible to appear electrochemical etching occurring on the aluminum wire reservoir if the surfaces of aluminum wire reservoir have not been hardened. Storage: It shall be sealed and stored indoor in the temperature 5~50℃. If you can store appropriately, no shelf-life will be required. Packing: Net weight 10kg (plastic bucket). The packing bucket of DIC-206 is our design patent. Without permission of our company, nobody can use this packing bucket. Molybdenum wire Molybdenum wire mainly refers to wire cutting with high voltage electric field in a continuous movement by molybdenum and other precious metals made material cutting workpiece, fine wire cutting machine is the continuous movement of the workpiece is called wire electrode (also called electrode), it can be pulsed spark discharge ablation, metal cutting the forming of the workpiece. There are many other uses of molybdenum wire. Chinese name molybdenum wire, foreign name Molybdenum, wire specifications, Phi 0.02mm--, Phi 12.0mm, use filament lead line, heating elements, wire cutting, also known as electrode wire Catalog 1 Introduction 2 uses 3 chemical composition 4 storage attention 5 Application of molybdenum wire After molybdenum wire diameter tolerance After the chemical composition of molybdenum wire Introducing editors English Name: Molybdenum wire Molybdenum wire Molybdenum wire The advanced hot and cold drawing technology is used to process high quality high temperature molybdenum raw materials into filamentous, which is used as an electrode for line cutting machine tools to process workpieces. Molybdenum wire surface state forming process: drawing, forging, polishing Application editor 1. pure molybdenum wire, GMPM., 1, used for winding wire core, bracket, lead wire, heating element, molybdenum foil belt, wire Application of molybdenum wire - Fast wire machine Application of molybdenum wire - Fast wire machine Cutting, auto parts spraying, etc.. 2., lanthanum molybdenum wire GMHI - M., 2, used for winding wire core, glass sealing parts, molybdenum foil belt, furnace heating materials, wire cutting, high temperature components, etc.. 3. yttrium molybdenum wire, GMHYM. 3, used for bracket, lead out line, electron tube reed, grid, furnace body heating material, high temperature component. 4. wire cutting special molybdenum wire GMPM. one, 1, GMHI.M., 2, for a variety of non-ferrous metals, steel and magnetic materials cutting. The utility model has the advantages of high strength, good discharging performance, high surface finish, fast cutting speed, long service life, etc.. Chemical editor Refer to the national standard GB/T3462 - 2007 related technologies of molybdenum bars and molybdenum slabs Index name GMPM. One, 1, GMH[.M. One, 2, GMHYM. A 3 The main content of M.% is more than 9990}99 45}99 45 % +%... 01 - 0501 - 05 Total impurity element% (01 (005) (005) W% = 001 = 001 = 001 Other impurities% = 0005 = 0005 = 0005 GMHI.M2, GMHYM. One, 3 for rare earth, high temperature lanthanum, yttrium molybdenum, Rare earth element not an impurity meter. Standard of dimensional tolerance for molybdenum wire production: national standard GB/T4182 - 2003 "molybdenum wire" Specification: Phi 0.02mm-- phi 12.0mm Other applications: hook, core, grid, side rod, rod, lead line, etc. At present, domestic manufacturers of molybdenum wire are: Shandong, Nanjing and other bright diamond, Fred Characteristics of molybdenum wire as electrode wire: Ultra high tensile strength; It has high surface finish, good stability and high cutting accuracy; Elongation rate is small, tight silk is small; The winding rate is large, the wire diameter is uniform, it is difficult to break the wire, and the service life is long; Increase the high frequency power and improve the rough machining efficiency; The accurate measurement, vacuum packaging, prevent oxidation mildew, can be stored for a long time. Save note editor Keep the molybdenum wire in a low ventilated and cool place. Please keep the temperature as high as 20 degrees to 25 degrees to avoid the oxidation of the molybdenum wire; Molybdenum wire placement for more than 6 months may cause perpendicularity problems. Advantages of molybdenum wire: The accuracy of molybdenum wire is high, and the line diameter tolerance is controlled within 0 ~ 0.002mm; The breakage rate is low, the processing speed is high, and the cost performance ratio is high; Stable long time continuous machining can be realized. The main features of the counterfeit molybdenum wire are the following: 1. The number of molybdenum wires cut by counterfeit wires is 100 to 200 meters shorter, and the net weight of molybdenum wire is not enough. 2, fake wire cutting molybdenum wire disk weighing 120 - 130g, or the actual plate weight is more than the plate weight 20 - 30g. The net weight of molybdenum wire increases by 20 - 30g, and some molybdenum discs weigh about 98G. 3, counterfeit wire cutting molybdenum wire box outside label data and the number of wire labels do not match. Application editor for molybdenum wire The molybdenum wire is applied to profile cutting, H2 furnace, heater rod, guide bar, hook, mandrel, wire, lead, etc. Molybdenum shall be used in the manufacture of high temperature resistant equipment, such as brackets, guide rods, heating rods in furnaces, etc.. The molybdenum wire is mainly used for the high temperature field of the molybdenum furnace and the electronic tube socket. The molybdenum wire is a refined molybdenum rod. It is divided into white molybdenum wire, black molybdenum wire, spraying molybdenum wire, molybdenum wire used for wire cutting, etc.. Molybdenum wires are often used as materials for heating high temperature furnaces, heating materials for supporting materials, wire mesh, etc..

2017 09/04

- HANQI EDM CIMT 2017 Machine Tools exhibitionCIMT 2017 15th China International Machine Tool Show Date: 4/17/2017 - 4/22/2017 Venue: New China International Exhibition Center (NCIEC), Beijing, China China International Machine Tool Show (CIMT), sponsored and organized by China Machine Tool & Tool Builders' Association (CMTBA) was first launched in 1989. It is the largest and most influential machine tool show in China, and is recognized as one of the four largest international machine tool shows in the world.

2017 05/05

- CNC Wire Cutting EDM Machine cutting sampleCNC wire Cut EDM machine cutting sample In the thread processing because of no residual stress, high processing efficiency and other advantages are widely used in mold industry and aerospace field. The workpiece in the thread cutting process includes the steps such as the ladder hole, the wedge table, the circle and the ellipse. The thickness of the workpiece will change continuously or abruptly along with the processing. In fact, without changing the processing parameters of the case, with the workpiece thickness decreases, the servo processing speed will gradually become faster, resulting in discharge concentration, and prone to broken wire phenomenon; the other hand, the workpiece thickness increases, the servo processing speed will Gradually slow down, resulting in reduced processing efficiency. Therefore, when the workpiece thickness changes during processing, how to make the machine servo feed speed with the workpiece thickness changes in a desired range, is to ensure that the wire cutting processing accuracy and processing efficiency of the important prerequisite, and online identification of the workpiece Thickness is the problem. In recent years, scholars have done a lot of research on the identification of the thickness of wire cutting workpiece. For example, the ability of the pulsating power source, the use of erosion of the material volume and discharge energy ratio of the specific discharge energy concept, the establishment of a workpiece thickness, processing speed and discharge frequency between the data model is suitable for predicting the thickness of the workpiece changes little Wire cutting processing. The feed vector, the feed rate and the pulse interval are chosen as the input, and the support vector regression model of workpiece thickness identification is established to predict the workpiece thickness more accurately. At present, the research on the thickness of the wire cutting thickness is mainly in the one-way wire cutting machine (walking machine), and the workpiece thickness identification is mainly based on the use of energy pulse power in the wire cutting process in the discharge frequency, pulse interval , Feed rate and other factors to predict the model to achieve the workpiece thickness prediction. But these models are based on the establishment of the line cutting gap in the case of the same, and tie the actual processing process, the different processing parameters generated by the line cutting width is changing. At the same time, the type of pulsed power supply is not only a kind of energy pulse power supply, which has caused the limitations of the current technology. Above for the "walking thread cutting can achieve automatic identification of workpiece thickness," the introduction, but so far, can only be achieved in the walking machine. Suzhou Hanqi is a professional manufacturer of wire machine tools, technical cooperation with the Swiss company, machine tool accuracy can guarantee 10 years!

2017 03/04

- Wire EDM machine market analyzeWe are the best quality molybdenum CNC wire cut EDM machine, ZNC EDM sinker, CNC EDM sinker, EDM Driller manufacturer in the market We take other competitor CNC wire cut EDM machine, EDM sinking machine to compare Looking forward your cooperation in 2017 new year!

2017 02/16

- How to estimate wire cut machine quality by cutting sampleMost customers will be processed by a sample to determine the good or bad, in doing so there are many problems can not leak out, here to cite a few cases for your reference. Case 1) One customer has to purchase more than one threading EDM machine, because this customer has several step-and-drive before the threading machine, the use of one year after the processing index has been lost, the basic use of these machines Fast wire, so the customer is very cautious, with industry experts on a number of silk machine in the inspection, the choice of Suzhou Han Qi in the wire, very satisfied with the use of customers, and then decided to purchase one. Case 2) A customer to purchase wire walking machine, customers for high-precision gear processing, gear precision control in the class, and long-term maintenance. Customers in more than take the silk factory site visits, and finally select the Suzhou take the wire machine. After more than a year of long-term use, machine stable and reliable. Customers are buying Hatch 10 servo-threading machine. Case 3) A customer uses old type structure stepper drive mode of machine parts for processing, but the high-precision parts are out with slow wire processing. Since the purchase of the HANQI full servo in the wire, the outgoing wire processing parts are 90% of the wire used in the process of processing Hanche. Processing results to meet the requirements of long-term stability for customers to save the original. Case 4) One customer originally purchased multiple "C-type" step-and-drive (ie, swing-type) middle threading machines for automotive stamping die processing, which not only requires local processing but also multiple jumps Step processing, these machine jump positioning accuracy are greater than 0.02MM, unable to meet customer requirements, the use of wire walking machine processing costs too much. Later, through the introduction of customers to purchase the full servo servo wire walking machine, processing positioning accuracy are controlled within 0.01MM and so on Through the above several cases I believe we have to take the wire EDM machine with a new understanding of the following from a few aspects of in-depth understanding: 1 fuselage structure: There are two fuselage structure on the market at present, one is "British fork" machine tool structure, the other is "C type" machine tool structure, "C" machine structure is divided into: As the "font" and the fuselage base for the "T-shaped" structure of the two. From the stability of the long-term use of the fuselage, "C" structure than the "British fork" to be stable, C-type T-shaped structure (walking wire body structure) and more than C-shaped structure more stable . 2 Drive: Currently on the market in the wire-cutting machine tool has two drive methods, one is open-loop stepping drive, this drive from China's first research and development of fast wire machine so far nearly half a century has been in Using the drive method, it is widely used in precision fast-running wire machine. It can not achieve high-precision machine tool control. Another is the most widely used high-end CNC machine tools AC servo drive, it has a strong driving ability, high positioning accuracy and many other features, and through the computer for pitch compensation and backlash compensation, μ-class processing accuracy can be obtained And positioning accuracy, it is widely used in high-precision wire walking machine tools, machining centers and other CNC machine tools. 3 wire running way: the stability of the structure of the transport wire is essential, even if the precision machine do no matter how good, not a long-term stability of the wire transport institutions, everything will be out of the question. Molybdenum wire in the high-speed operation on the guide wheel will produce per minute 5000r-7000r high speed. Using the traditional fast-moving silk wire structure, to far can not meet the long-term use of silk threading machine molybdenum wire stability. 4 Water Filtration: The thread cutting machine must go through a good water filtration system, the impurities in the water fully filtered, because the processing power is very weak when the knife repair, water impurities brought about by the secondary discharge will make the entire processing loss Exhausted. 5 power control: power control part of the machine is the most critical part of its high reliability and long-term use is more important. Therefore, by simply processing a sample to determine the good or bad WEDM is wrong. For example, a stepper drive and a servo-driven machine tool to process a simple parts, the processing effect is not much difference, over time, the shortcomings of stepper drive will leak out, processing complex parts and skip processing Precision becomes worse and worse. Suzhou Hanci has developed a water-based cutting fluid, the use of water-based cutting fluid better!

2017 01/10

- CNC Milling&Engraving MachineCNC Milling&Engraving Machine This milling&engraving machine has provide wide scope of machining, such as milling, boring, drilling, tapping and various processes, especially suitable for machining various two-measure or three-measure concave-convex modes with complicated shapes and complex cavities and surfaces, as well as machining batch parts in various enterprises` workshop This machine composed carving function and milling function, it can engrave precision drawing and emboss on kinds of material like aluminum, brass, steel and nonmetal material. 1. Senior Meehanite FCD45C resin sand cast iron material 2. Full cover, separated cutting oil system, Chip-conveyor 3. Taiwan Syntec control system 4.X, Y, Z-axis adopt high precision imported linear guideway with big loading capacity and high positioning accuracy feature 5. The high-precision grinding grade ball screw, double nuts automatic transmission, high precision 6. The precision coupling, high speed, high torque, do not slip; 7. Hand controller 8. Automatic center lubrication system 9. High-performance control system, very easy to operate 10. The oil cooling system inside spindle. Outside cutting cooling system 11. The high-power, high-speed spindle oil cooler 12. Precision ER collet 13. The software is compatible with MaterCAM, Pro-E, UG, carving and other software, simple operation, widely used.

2016 10/27

- Who is GF AgieCharmilles?Suzhou HANQI CNC Technology Co.,Ltd full cooperated with GF AgieCharmilles to make FW Wire Cut EDM machine We are in charge the wire cut EDM machine production, sales and after service But who is GF AgieCharmilles? GF Machining Solutions is the world`s leading provider of machines, Automation solutions and services to the tool and mold making industry and to manufacturers of precision components. Products range from electric discharge machines and high-speed and high-performance Milling machines - including clamping and palletization systems - to 3D Laser surface texturing machines, services, spare and expendable parts, consumables, and Automation solutions. Based in Switzerland and maintaining a presence on 50 sites worldwide, GF Machining Solutions is a globally active group and source of strength to its customers. A company belonging to Georg Fischer Group (Switzerland), GF Machining Solutions has 2,873 employees and generated sales of CHF 867 million in 2013. GF AgieCharmilles' products range from electric discharge machines (EDM), laser ablation, high-speed (HSM) and high-performance milling (HPM) centers, through tooling, services, spare parts, wear parts and consumables and automation solutions. GF AgieCharmilles is the preferred partner to customers in the tool and mold-making industry and to manufacturers of precision and high-value parts. The key to their success is the success of their customers. Customers of GF AgieCharmilles are more successful than customers of their competitors. Their superior package of machine tools, automation solutions and services provides them with a measurable competitive advantage. Their customers` success enables them to gain new customers continuously. That is why they are increasing their market shares and why they are growing faster than others in the market in all regions of the world. EDM EDM can be used to machine conductive materials of any hardness (for example steel or titanium) to an accuracy of up to one-thousandth of a millimeter with no mechanical action. By virtue of these properties, EDM is one of the key technologies in mold and tool making. There are two distinct processes - wire cut and die-sinking EDM machines. GF Machining Solutions` solutions include hole drilling EDM.

2016 10/12

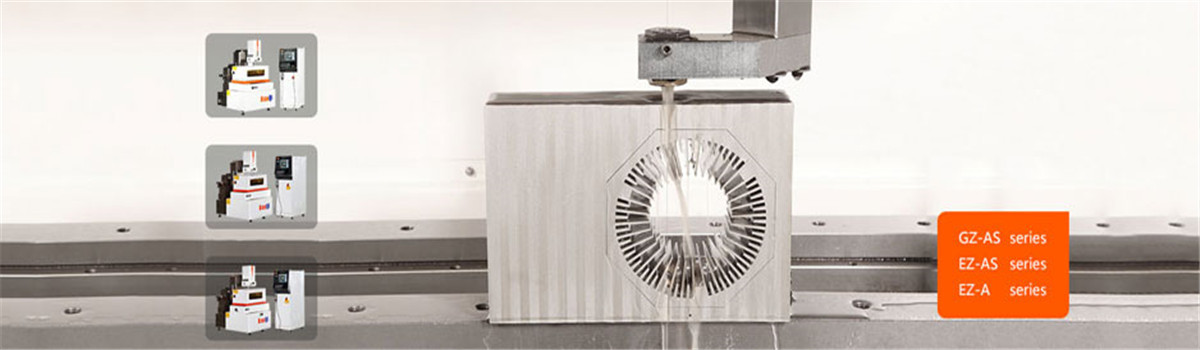

- Wire Cut Machine Cutting SampleHQ32GZ-AS wire cut EDM machine cutting sample AutoCut controller system based on Windows XP "C"structure "T"shape machine bed same with brass WEDM structure Special industrial computer LCD Japan Panasonic AC servo motor Hiwin linear guideway Hiwin ball screw Water tank similar with brass WEDM type Automatic lubrication and collect exceed oil system Automatic wire tension system High rigidity fixture same with brass WEDM Best finish: 0.0007mm Precision: +-0.0025mm LED working lamp Special Z device up and down

2016 10/09

- EDM Hole Drilling Machine workshopWe are manufacturer CNC 3-6 axis controlled EDM drilling machine and ZNC small hole drilling machine Also, supply small hole drilling machine consumables EDM copper tube, EDM brass tube, EDM electrode tube, EDM filter, EDM wire, EDM brass wire, electrode, ceramic guide, collet, drill chuck, rubber seal, filter for our small hole drilling machine. This type ZNC EDM drilling machine with cheap price, and steady working performance We sell it a lot to Europe machine tools market like Germany, Italy, UK... You are welcome send us inquire this small hole drilling EDM machine The follow as the EDM hole drilling machine production line If you required multiple axis CNC controlled small hole drilling EDM machine, we also supply you good solution

2016 09/07

- High Precision Wire Cut EDM Machine Cutting SampleThe follow wire cutting sample is cutted by hanqi high precision wire cut EDM machine HQ32GZ-AS You are welcome to visit our company and check it We fouce on EDM machine 30 years, supply wire cut EDM machine, samll hole drilling EDm, ZNC&CNC die EDM sinker machine and CNC machines It is ok you send workpiece drawing to us, and we cut sample for your checking

2016 08/26

- Wire Cut EDM machine cut aluminum materialIt is not very easy to cut aluminum material job by normal CNC wire cut edm machine because of soft and chip problem. Too much chip when cutting process, it affect spark discharge and the power feeder will be weared too much It need special design aluminum material wire cut EDM machine Please check the follow cutting sample by our machines We are 30 experience on EDM machines, and support turn key solution to customer If you have any question about EDM machine, we like share our experience

2016 08/21

- CNC Die EDM Sinker Machine Erosion SampleIt is easy to machining high precision and low roughness workpiece by our CNC die EDM sinker machine The follow samples is made by our CNC erosion EDM machines, the roughness from high to fine, the most important is the angle is very clearly The EDM machine machining video is possible if you need Youtube video https://www.youtube.com/watch?v=wEHCh7W5YWA

2016 07/31

- 40 sets Wire EDM Machine DeliveryWe need delivery out 40 sets high precision CNC molybdenum wire cut EDM machine to one customer in July 2016 The machine special design with the working alarm lamp, and special metal plate cover We are appreciative the customer choose us and trust us We delivery machine day and nigh to save time

2016 07/13

- Oversea MarketMore and more oversea customers choose our EDM machine High precision, easy operation, long working time,good roughness

2016 07/07

- 200 sets Wire EDM Machine OrderThank you dear customer trust us A very big and famous customer purchase total 200 sets CNC multiple cutting EDM Machine from Hanqi We supply best service and machine The first 20 sets

2016 07/07

- 2016 China International Machine Tools Exhibition2016 China International Machine Tools Exhibition

2016 07/07

- 2016 Shanghai DMC Die Mold ExhibitionShanghai New International Expo Center China 2016 Die Mold Internation Exhibition HQGZ32-AS Wire Cut Machine Agie Charmiles wire Cut Machine G35 Mirror Finishing CNC EDM Sinker Machine

2016 07/07

- HANQI and GF AgieCharmilles Full CooperationGF AgieCharmilles supply FW CNC Wire Cut EDM Machine all technology to us We make FW CNC Wire Cut EDM Machine, and in charge sales, service, spar parts support

2016 07/07

- Wire EDM Machine Problem Solution1. Low Cutting Speed/Low processing efficiency 1) the initial discharge of low processing efficiency ----- electrode size scaling amount (spark-bit) to a large, automatic programming can choose a larger number of current conditions. To the extent possible pre cavity milling. 2) low discharge machining stage efficiency program in the middle of each segment condition ----- margin between too much can also be reduced allowance between two segments. 3) low application efficiency ----- final paragraphs EDM machining using the timer function to effectively control the finishing time (need to set the processing time). 4) the area is too small ----- system input area limitation threshold, even if the amount of scaling electrode size is bigger, because the area is too small, it does not produce large discharge conditions. Such cases can be appropriately increase the area of human values entered. 5) the incorrect application type ----- choose such a large cavity is actually processed and the choice of the "standard" type of application. All application types "microfabrication" the least efficient. 6) processing priority ----- Choose low loss priority is low efficiency, choose a high priority is speed and efficiency, the loss is too large. 7) discharge, carrying the knife combination unreasonable ----- according to the processing status, carrying knives to adjust the height, the discharge time match. 8) ----- optimization parameters decrease pulse interval P, to increase the servo reference COMP. 9) the use of improved technology ----- graphite electrodes, greatly enhance the overall productivity 2. Big electrode wear 1) ----- improper use parameters should be used as a low loss priority processing parameters. Small electrodes can choose the type of micro-machining applications. 2) discharge condition number is too small electrode tip ----- For, you can not use a large current process. 3) discharge energy is too small, resulting in inefficient processing time of discharge electrodes and electrode loss ----- if accompanied by a large loss when the processing speed is too slow, increase processing efficiency. 4) the electrode material is not good ----- use high purity copper, or even lower loss Luoyang Copper is a copper tungsten alloy as the electrode material. 5) increasing the pulse width is too small ----- condition number of the pulse width T, can significantly reduce electrode wear. 6) ----- low-loss pulse waveform, a tapered discharge waveform pattern (Mode10) 3. points in the inaccurate position deviation 1) using conventional methods, "the electrodes touch points in the workpiece", because points belonging to surface contact between the electrode and the presence of a number of factors will affect the points in the workpiece accuracy ----- recommended "base ball-point divide in "positioning method. Work bench fixed a benchmark ball as a reference, prior to processing in the spindle head clamping a benchmark ball points on the workpiece, and then on the workbench reference points in the ball, so you get a distance relationship, after all the reference electrode are points in the ball. 2) the electrode and the workpiece datum accuracy, ensure the accuracy of debris ---- electrode and the workpiece datum, and wipe clean. 3) perception of speed is not too fast (Set F: 75mm / min) 4) Use precise clamping and positioning system. 4.The machined surface roughnesss 1) electrode material is not good, there are impurities ----- high purity copper or copper Luo. 2) translational inappropriate choice ----- Use DOWN / ORB translational, and finishing process using a timed section. 3) improper spark oil, spark oil viscosity big spark ----- finishing oil suitable replacement. ----- Appropriate parameters need to be optimized to reduce the discharge time TEROS, increasing the pulse interval P, reduce the servo reference COMP. 4) red liquid mode uneven ----- finishing punch was not additional local. 5) matte surface treatment ----- difficulty factor, and recommend process to VDI14, more sophisticated processing surface of its conditions are demanding. 6) surface effects ----- priority standard of priority is generally better than a low loss priority. 5. The mirror effect is not good 1) Some of the workpiece material can not achieve mirror finish effect, such as SKD11, Cr12MoV, DC53 (most metal stamping die steel) ----- recommend using a mirror finish steel, such as SKD61, S136,718HH, NAK80 etc., or correct understanding deviation . 2) processing area is too large, reach a uniform mirror effect ----- area larger than 25 square centimeters should use the mixed powder processing. 3) translation inappropriate choice ----- Use DOWN / ORB translational, finishing with a timed processing function. 4) processing area entered incorrect ----- enter the exact processing area, so that the system automatically set the timer. 5) ----- mirror finishing segment conditions according to the processing status, carrying knives to adjust the height, the discharge time, carrying the knife to match the speed, do not use the red liquid, the liquid flow to be small. 6) the beginning of the process, the discharge is unstable, often carrying knives The system automatically detects, the impact of adaptive ----- shutdown condition numbers of some automatic protection function (ACC2 / ACC4), reduced sensitivity MS, or the discharge time and carrying knives height control is set in accordance with User settings (User / Fix), so lift the knife presented as a regular, controlled state. (Not recommended, often this instability is having a protective effect) 7) ----- optimize processing parameters to optimize the discharge time, carrying knives height, carrying knives rate, pulse gap servo reference. 6. Processing size failed 1) small size after processing ----- Typically, the size processed using an automatic programming will Shaopian small, which is more secure. 2) Electrode size tolerance ----- check the electrode size, which is the premise. 3) ----- high dimensional accuracy according to the machining conditions, pre-processing, the size of the measured and processed electrode size, adjust translational radius. 7. how to process multiple workpieces A plurality of processing a plurality of workpieces How to use ----- workpiece relative parts function, each piece is set to a relative zero, each piece of the current machine coordinate value memory, the program can take any of these relative zero transfer In order to achieve continuous processing a plurality of workpieces, these artifacts should be set up in the same tray (Mag Pos set to the same value). 8. What are the main points of carbide EDM 1) When the automatic programming to choose carbide processing parameters. 2) If there are higher requirements for electrode wear, rough machining of positive polarity may be used to reduce the electrode loss (the default parameters of the machine are negative, in fact, using the negative impact of thermal processing parameters thin, die life the best, but the loss is large, a plurality of electrodes need to be replaced.) 3) the use of a copper tungsten electrode material, can significantly reduce electrode wear, reduce the number of electrodes.

2016 07/07

Email to this supplier